Compressed Stabilized Earth Blocks compared with Fire-burnt clay Bricks

Production of fire-burnt clay bricks in field kilns is highly polluting! Our company researched alternatives and choose the use of CSEB. IHS starts Production as well as construction in 2016. Compare for yourself:

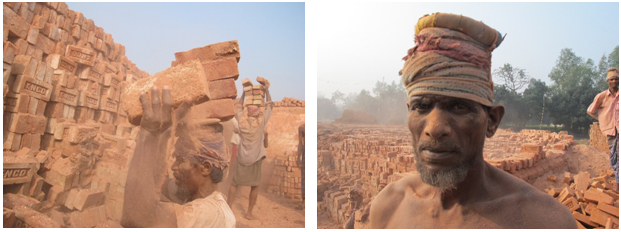

WORKING CONDITIONS

Working conditions in the brick kiln are harsh. Dust entering the longs, heavy loads carried on the head, poor lodging conditions are threats to the health of the workers.

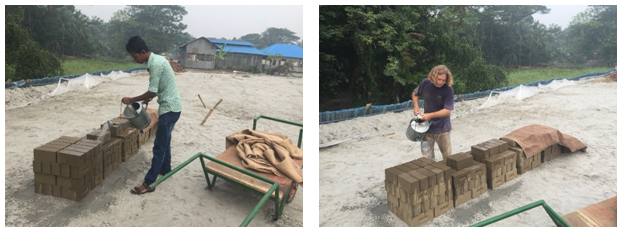

Compress the mix of soil, sand, cement in a mechanical hand press (IHS will soon import an automated hydraulic press)

EMISSION GREENHOUSE GASSES

According to WB, more than 5.000 of coal-fired outdated brick kilns are the cause of heavily air pollution. They are the main source of fine particulate pollution in Dhaka and the CO²-emission is estimated at 9,8 million tons. CSEB production does not need burning: the blocks are simply cured and dried in the sun. CSEB uses (max. 10%) cement and the estimated CO² emission for production of 1kg cement is 0,8Kg.

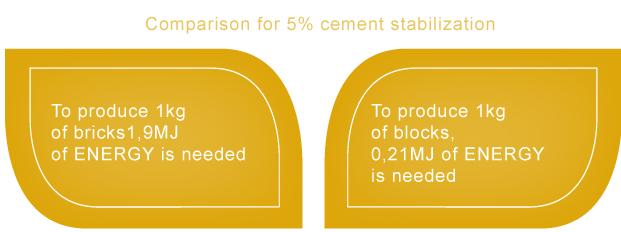

EMBODIED ENERGY

Coal-fired brick kilns annually burn 3,5 million tons of low quality coal (3,5-4% sulfur content) and 1,9 million tons of firewood. CSEB does not burn but dries in the sun. It uses a low percentage of cement (max 10%) for which 4,2MJ/kg of energy is used.

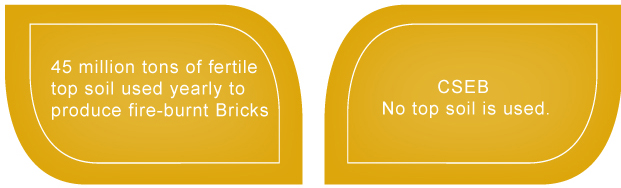

USE OF FERTILE TOP SOIL

Brick kilns have a negative effect on agricultural productivity as they use the fertile top soil. Annually 2,600 hectares of agricultural land is depleted of its fertile top soil. In addition acid deposits (SO² and NOx emitted from the brick kilns) negatively affects agriculture.